-

- ABOUT US

- Introduction

- History

- C.I

- Certiticates

- Relations

- Location

-

- TECHNOLOGY

- Scraping

- 3D Design

- Cover

- Measurement

-

- CONTACT US

- FAQ

- HOME

- BUSINESS

- BUSINESS AREA

Leading Changes. MPRO

BUSINESS AREA

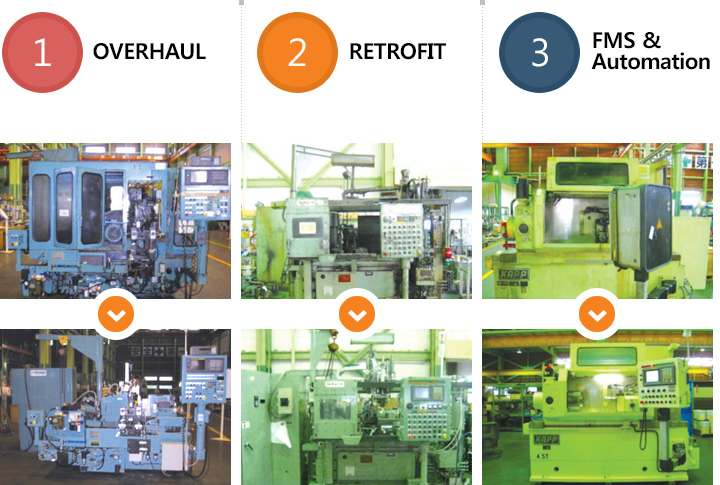

OVERHAUL

Restore your functional problems caused by deterioration such as degradation of precision and temporary loss of function

Because the problem from huge and complicated machine/process-lines need totally different access with those from small and simple machine, the customer needs our expert team who can suggest the optimum solution based on professional, experience-based diagnosis. The solution also comes with consideration of management value, such as cost=benefit analysis.

With our solution, customer will experience enhanced performance further than before the problem.

With our solution, customer will experience enhanced performance further than before the problem.

RETROFIT : Enhance the precision of a general machine by adding CNC function

RETOOLING : Renovate customer’s existing product line in order to add or change product spectrum

Traditionally, manufacture completeness depends on the know-how and skill-level of operators. But nowadays it becomes possible to get more mechanically precise mass-output with appearance of NC (Numerical Control) function. CHEIL realizes the best NC application on customer’s facilities by means of all electrical and instrumental technology, builds the circumstance compatible with existing lines, and finally makes customer’s manufacture process optimization.

FMS & Automation

Realize the automation of workpiece logistics by applying Gantry Loader & Robot System

Centralize the control system by installing LMS (Line Monitoring System)

Diversified need of final customer has caused production paradigm shift; mass-production to “small quantity batch production”. It also demands that those parts and accessories of production lines should have flexibility in order to respond to often-changing product schedule and short product life cycle. FMS (Flexible Manufacturing System) arises to satisfy such needs, in other words, relatively high productivity as well as flexibility on process.

CHEIL has developed own technologies and accumulated experiences, so we are always ready to answer to customer’s such needs from huge product line to each machine.