-

- ABOUT US

- Introduction

- History

- C.I

- Certiticates

- Relations

- Location

-

- TECHNOLOGY

- Scraping

- 3D Design

- Cover

- Measurement

-

- CONTACT US

- FAQ

- HOME

- TECHNOLOGY

- SCRAPING

Leading Changes. MPRO

TECHNOLOGY

SCRAPING

The guide way, which means a casted-iron standard way for making a machine operate precisely, must have equable surface and high hardness, through special process and heat-treatment. Also, the distance between the guide way and its opponent way should be set in order to satisfy both high proximity and low functional force. Otherwise, you might suffer by unexpected vibration, machine abrasion, and accuracy-decrease caused by rough movement of machine. Scraping is the solution on these problems.

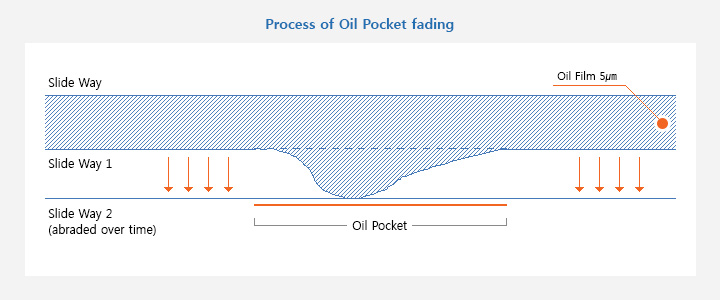

In the regular operation, about 4-5 micron depth of oil pocket lies between the guide way and its opponent way. If there is no oil pocket build by scraping, approximately 0.03-0.05mm abrasion will occur on the slide way of machine in normal operating condition. Those abrasion worsens the precision in the slide action over time, and finally damages qualities of final product.

CHEIL’s appropriate scraping work will reduce the degree of annual abrasion of your machine down to 0.01mm by forming and maintaining oil film, and triple the life of slide part. Also, after initial installation with scraping, oil pocket fades away gradually by abrasion of slide way, which inversely accelerates abrasion of slide way. The additional scraping work periodically will sustain precision degree of slide machine.

The optimized scraping work requires highly accumulated experiences and know-how, so CHEIL standardizes the process and the approach method. Because the problem occurred by inappropriate scraping work can’t be resolved by any treatment to other part of the machine, we fully understand the importance of scraping when assembling machine, and invest sufficient time and extreme concentration.

CHEIL has constantly raised completion level of scraping work through enthusiastic R&D with Japanese partner and various experiences, and now we have a pride as the best technology group in this field..